This article describes FPC warpage and related preventive measures. These measures, as a follow-up to the previous course, are important for reliably soldering FPCs. Please refer to it by all means.

The previous course explained that rigid circuit boards tend to warp in a certain direction.

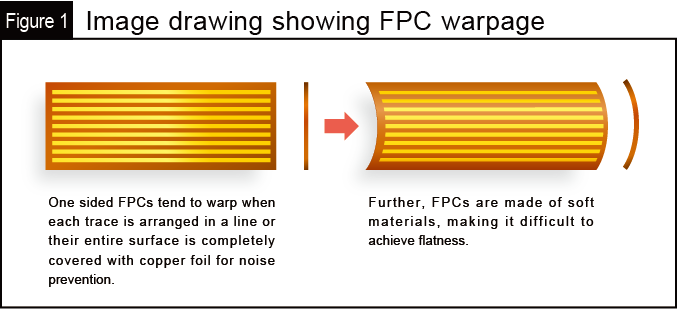

FPCs as well as rigid circuit boards tend to warp in a certain direction.

In general, FPCs are composed of polyimides, copper foil, and adhesives stacked in layers. All individual layers are made of different materials and have different contraction rates. Therefore, FPCs do not uniformly contract when heated during reflow soldering and may warp.

In particular, one-sided FPCs tend to warp when each trace is arranged in a line or their back side is firmly covered with copper foil for noise prevention.

The occurrence of FPC warpage in this manner will cause poorly soldered joints during connector mounting.

Therefore, it is important to take measures for preventing such FPC warpage during reflow soldering.

One such effective measure is to fix FPCs flat during reflow soldering.

There is a commercially available jig for securing FPCs on a sticky base so as to prevent them from warping.

Making effective use of such a jig helps prevent poorly soldered joints.

How did you go with the explanations above? This course introduced measures against FPC warpage. We would be happy if this article were helpful to you, even a little, for taking measures against poorly soldered joints during connector mounting. Please implement designs for preventing poorly soldered joints by referring to the previous course.