This article and the next introduce the structure and features of FPCs, FFCs, and membranes, based on questions from customers. This is Part 1 and covers FPCs and FFCs in detail. Please make use of the following information when designing devices.

Flexible PWBs, such as FPCs, FFCs, and membranes, covered in this and the next course are indispensable for achieving the downsizing, higher density, higher performance, and reduced weight of devices.

They are thin as well as flexible, thereby allowing circuit connection even in a limited space.

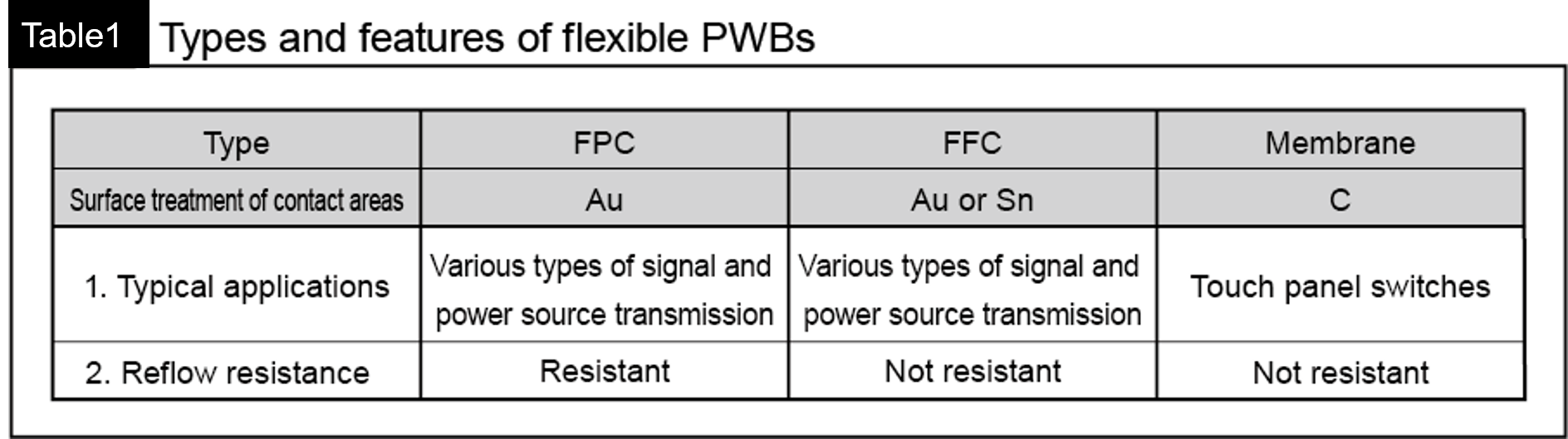

FPCs, FFCs, and membranes are all flexible PWBs; however, their manufacturing methods are different. Therefore, they have individually different features in regards to applications and heat resistance.

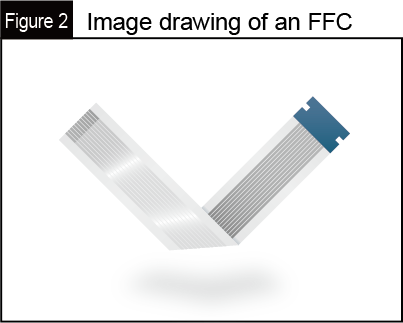

FFC is an abbreviation for Flexible Flat Cable. This wiring material is produced by arraying flat thin electric wires in parallel lines and sandwiching both surfaces of the arrayed wires between PET insulation films. (Fig. 2)

Au or Sn plating is used for the surface treatment of the contact areas.

FFCs are an array of copper wires; therefore, they allow only straight wiring unlike FPCs.

1. Applications

Both FPCs and FFCs are used for connecting signals and power sources.

FFCs are frequently used for the electric connection of medium-sized home appliances, such as OA home appliances including copiers and fax machines.

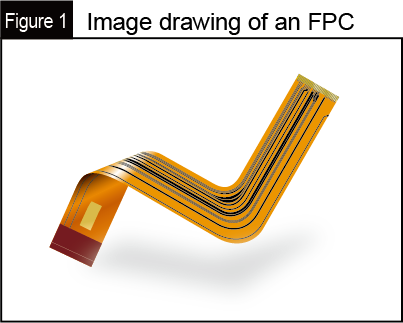

On the other hand, FPCs are superior in flexibility and allow higher density wiring in comparison to FFCs; therefore, they can even be used for compact mobile devices, as well as, for automobiles and robots.

2. Reflow resistance

Since the surfaces of FPCs are covered with polyimide, they have excellent heat resistance. Therefore, components such as connectors can be reflow mounted on FPCs.

On the contrary, the surfaces of FFCs are covered with PET materials; therefore, they do not have high heat resistance that would allow for reflow processing.

Components can be reflow mounted on FPCs, which can be used not only for FPC connectors but also for narrow pitch connectors, each of which consists of a socket and a header to be fitted.

FPCs and FFCs have similar names; however, their appearances and specifications differ in these specific ways.

Since their basic applications are the same, some of you may use both FPCs and FFCs.

Panasonic provides many types of connectors applicable to FPC connectors and 2-piece type stacking connectors. In addition, the Y5B series connectors are also applicable to FFCs.

How were the above explanations? This article explained the respective features of FPCs and FFCs.