In this article, we will discuss the terminal flatness of a connector, based on inquiries from customers. We will also mention some points that you should heed when soldering a connector. We hope this article will be of great help in your design work.

Let's start with the meaning of the term "terminal flatness of a connector."

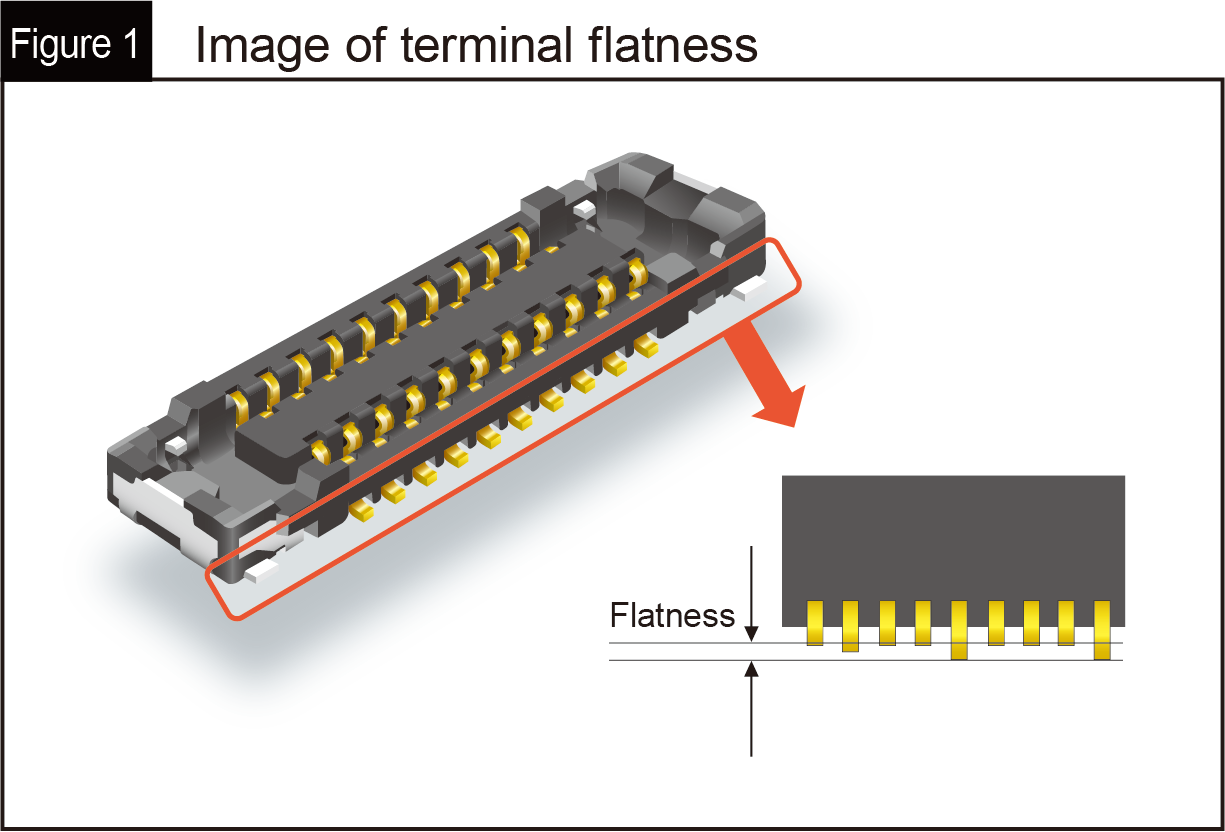

As you can see by referring to Fig. 1, the terminal flatness of a connector refers to a degree of unevenness of a row of soldered terminals (signal terminals, metal terminals, etc.) making up the connector.

Specifically, this term indicates a level difference between a terminal located at the lowest position and a terminal located at the highest position, both terminals being among an array of soldered terminals making up one connector.

Zero terminal flatness is ideal from the design point of view. Arranging all terminals in such a way as to give them the same height, however, is difficult in actual cases of manufacturing connectors, in which slight unevenness of terminal heights is bound to result. A degree of such unevenness is thus defined as "terminal flatness of a connector."

Why is this slight degree of unevenness so important?

The answer is that the terminal flatness of a connector significantly affects the solder characteristics of mounting the connector.

When the connector is mounted on a board, if the terminals making up the connector are arranged unevenly, degrees of soldering the terminals turn out to be non-uniform, which may lead to lower soldering strength as a whole. In the worst scenario, some terminals are left unsoldered, causing a soldering failure (poor soldering) case.

Stable terminal flatness (nearly zero), in contrast, helps prevent insufficient soldering strength or soldering failure (poor soldering). You can imagine that from the above description.

Since the terminal flatness is an essential factor related to the mounting of connectors, connector manufactures, including Panasonic, guarantee proper terminal flatness values. To find specific terminal flatness values, check specification diagrams of individual products.

To allow customers to mount connectors properly, our company's specifications specify recommended board patterns, recommended metal mask screen process charts, and recommended reflow profiles. If you intend to use them, check them first.

Well, that's what we've got for you today. In this article, we have talked about terminal flatness.

In recent years, we have witnessed a growing trend in miniaturization of components and improvement in processing precision and soldering techniques and come to face the fact that connector mounting is not so easy anymore. But, if you check specifications and manuals properly, you can solder (mount) connectors correctly. So, remember what you've learned from this article and make the best use of it in your design work.