Panasonic Industry connectors for Automotive applications

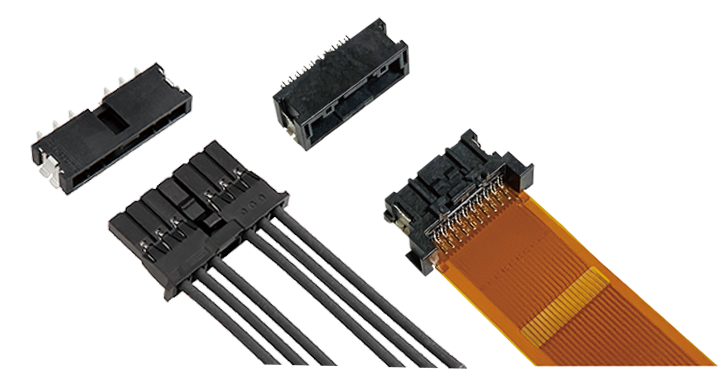

Panasonic Industry offer 2 types of Connectors for Automotive applications: board-to-wire and board-to-FPC(Flexible Printed Circuit).

Suitable for automotive applications that require a high shock, vibration, and heat resistance (125℃), we offer customers with a wide range of benefits of our highly reliable connectors and improved workability, not limited only for automotives, but also for other applications such as industrial robots and drones.

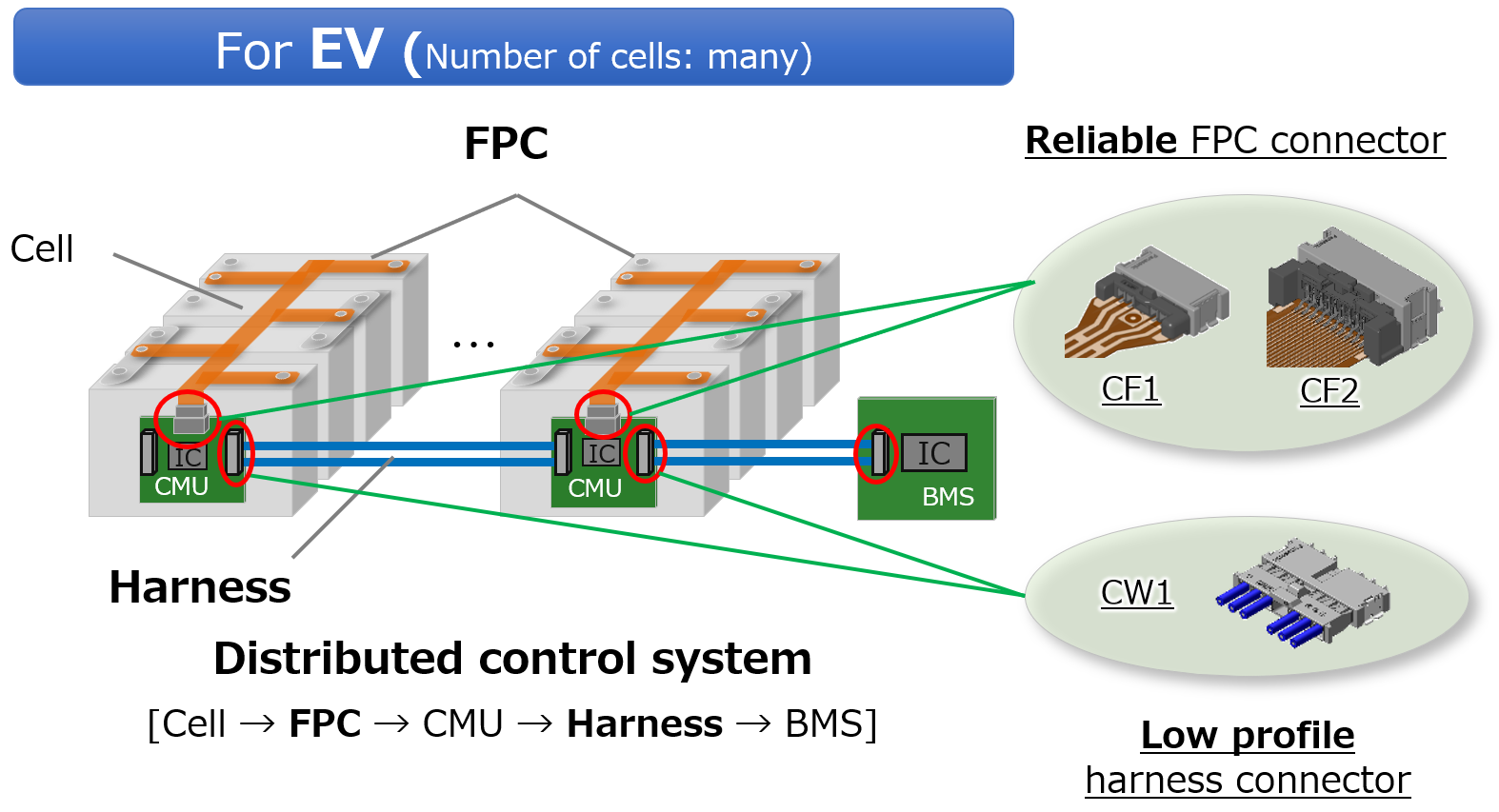

Trends in Automotive Wiring

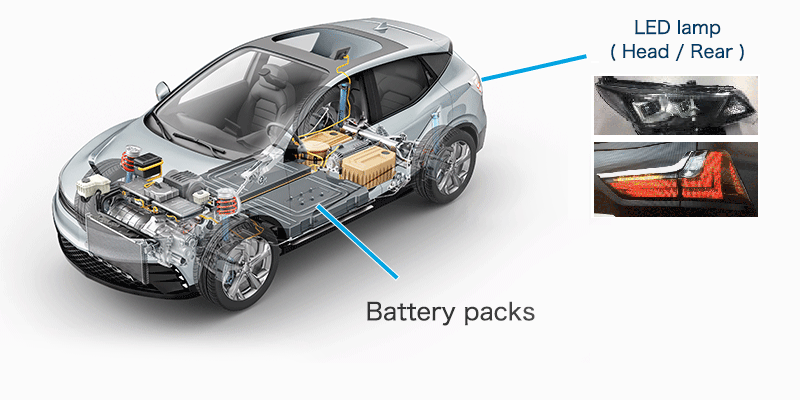

The use of FPCs for automotive wiring has been progressing in recent years, for weight and space saving.

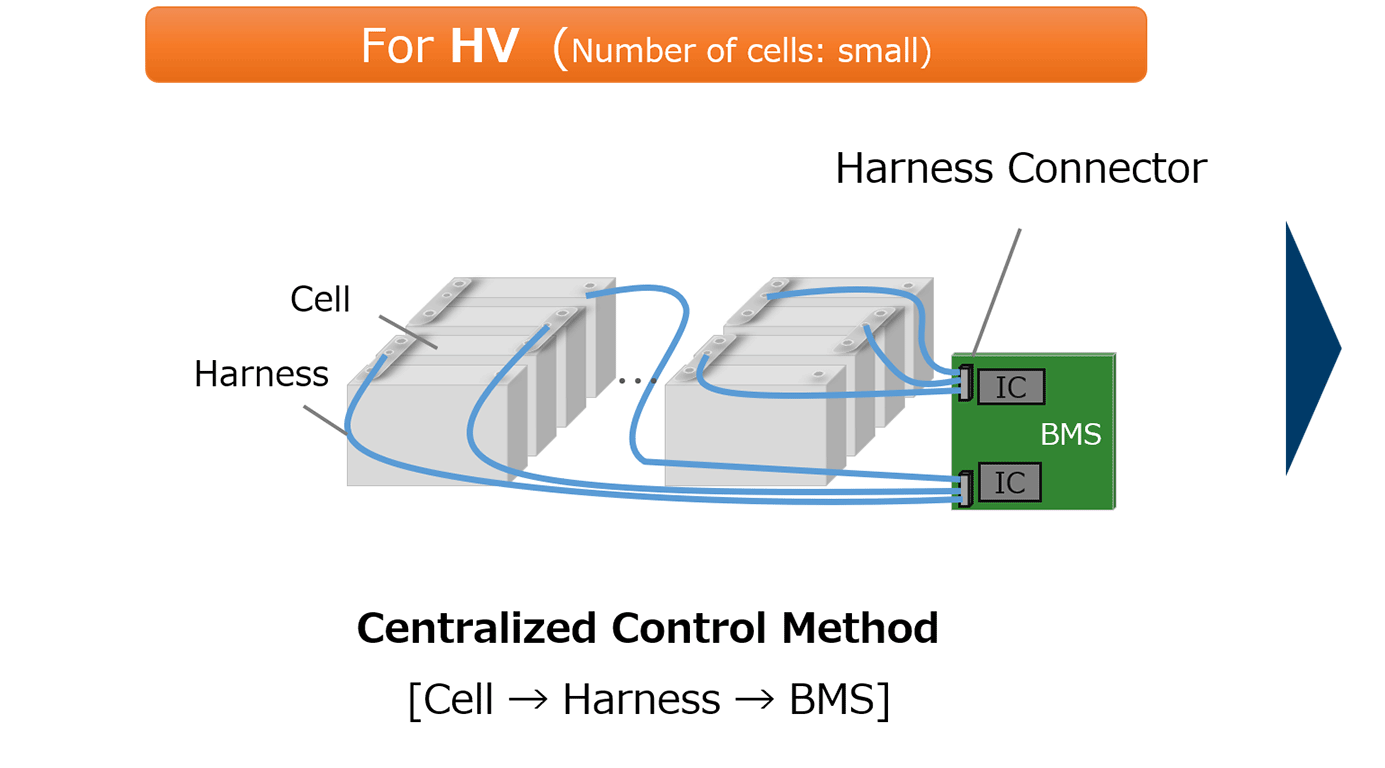

In particular, the FPCs have been widely applied in voltage monitoring wiring (CCS*) for BMS**, and LED lamps.

*CCS: Cell contact system, Cell Connection System, Cell Contacting System

**BMS: Battery management system

Application examples

With the expansion of driving range of EV/PHEV, a demand for larger battery capacity has been increased.

Our board-to-FPC connectors provide a better solution to meet this growing trend of miniaturization and height reduction of the module.

Features

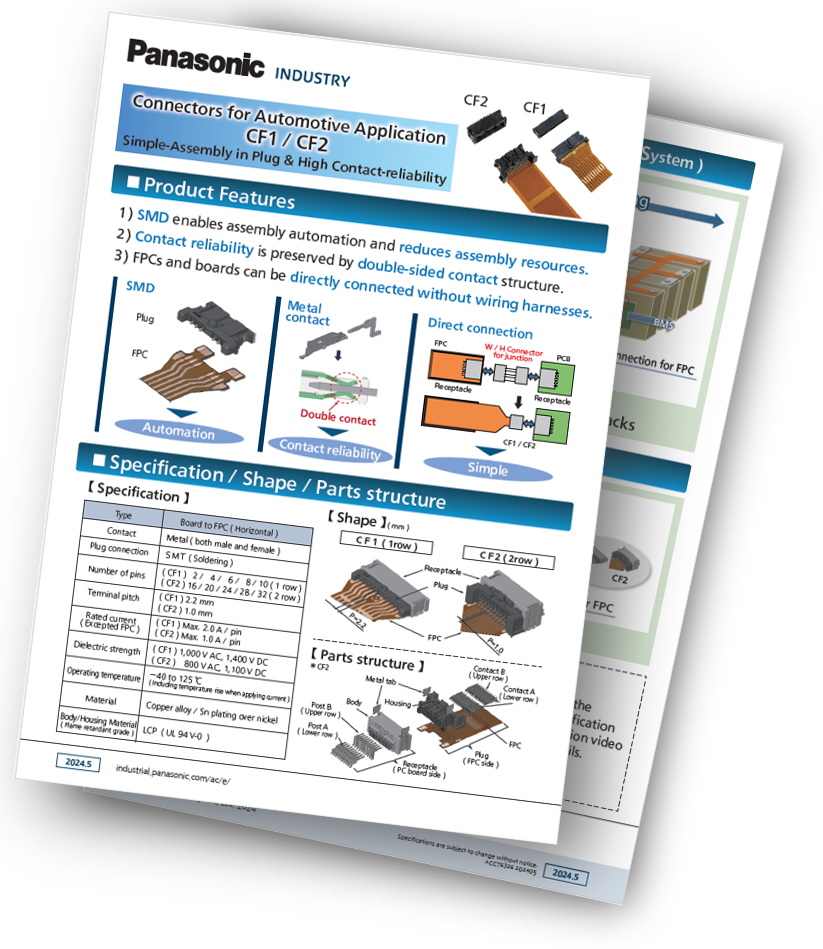

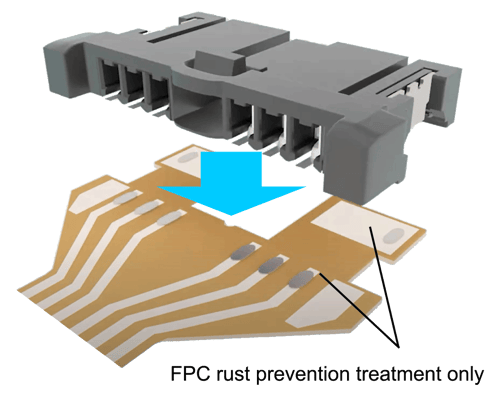

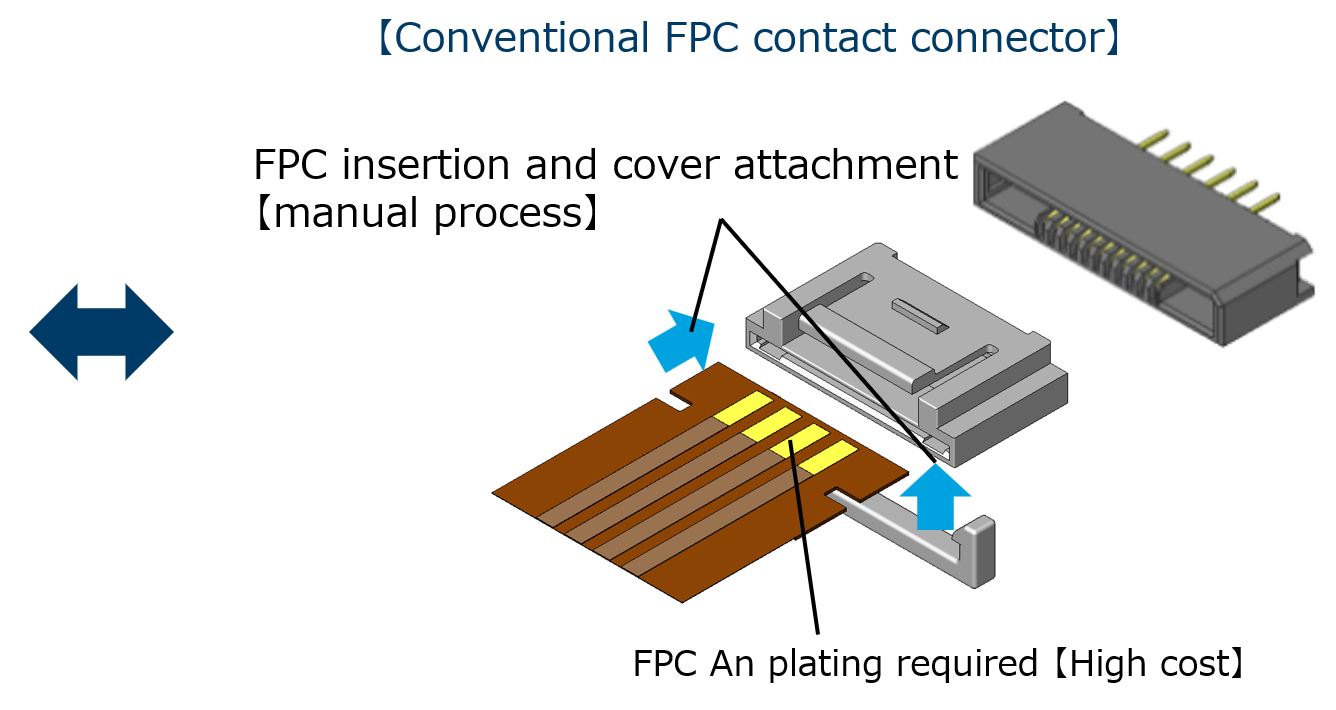

Reduced man-hours in assembly process and FPC costs

The plug assembly is completed in one reflow soldering process, which contributes to reducing assembly process. Moreover, it can be simultaneously mounted with other parts such as thermistors and LEDs, enabling assembly automation.

▮Plug assembly is one reflow soldering process.

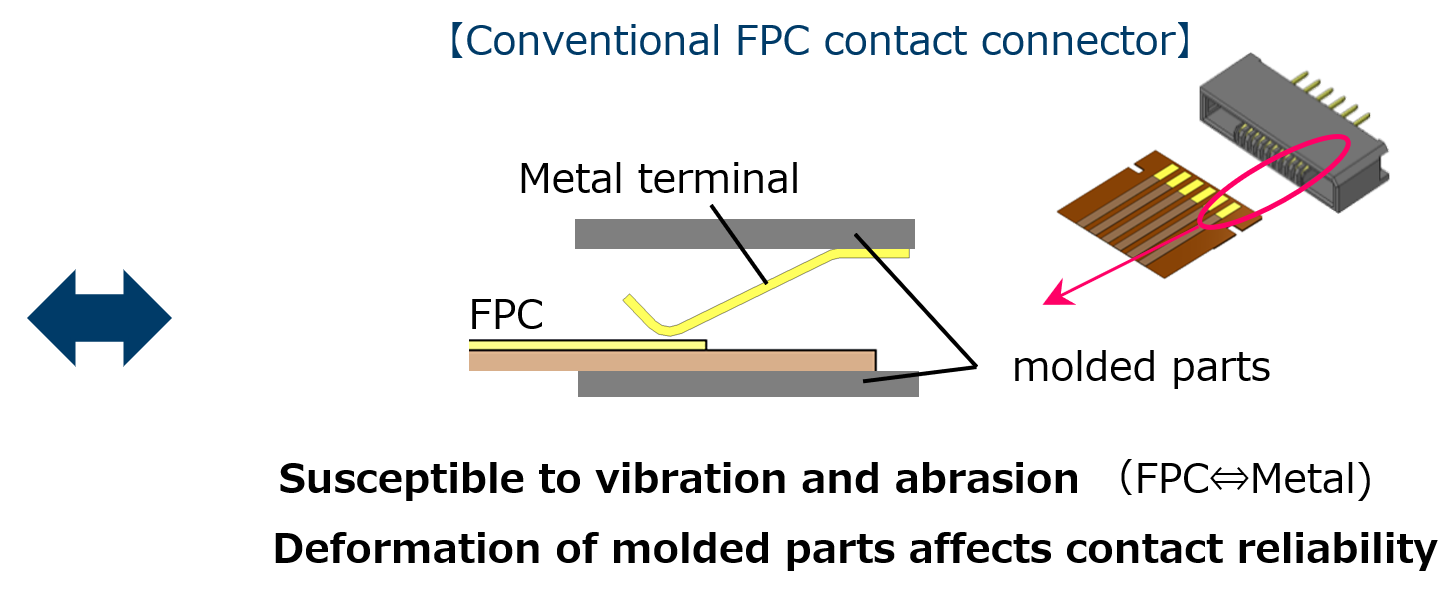

High contact reliability with metal contacts

Connector mating is completed in one action of inserting the FPC side connectors (Plug) to PCB side connectors (Receptacle).

The contacts of the CF connectors are consisted by metal terminals on both sides of plug and receptacle, and have a double contact structure with bent spring terminals. This makes the connectors resistant to foreign materials and vibration wear, ensuring high contact reliability for the in-vehicle environment.

This enables FPC direct connection wiring instead of conventional harness wiring, contributing to the reduction of harnesses and connectors.

▮Metal on both sides/ Double contact structure

▮Direct connection between FPC and board

●Reduce Wire Harness in the BMS

Horizontal and vertical configurations offer greater flexibility in board layout design

We are developing connectors with additional pins and horizontal and vertical configurations, to enhance the flexibility of our customers' module designs and board layouts. Please feel free to contact Panasonic Industry for more information about our line-up and other requirements.

Space saving with low-profile connector

CW1 is the industry's low-profile connectors for automotive applications with a height of only 3.4 mm.

The compact connector saves space and allows effective use of the PCB area.

Lineup

* CF1: 2 pins (Under development), CF2:16, 24, 40 pins (Under development)

If you have any other requests, such as the number of pins not shown in the above table, please feel free to contact Panasonic Industry.