Touch Panels

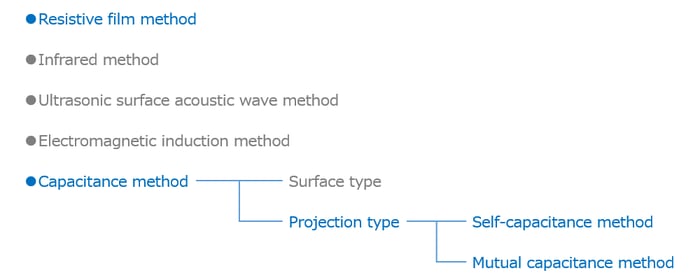

Type of touch panels

Panasonic mass-produces the resistive film method and the capacitive method among the many touch panel methods.

Utilizing Panasonic’s unique features, it is used in a wide range fields.

| Touch method | Resistive method |

Capacitance method |

Infrared method |

Ultrasonic surface acoustic wave method |

|

| Display performance |

Transmittance | △ | ○ | ○ | ○ |

| Parallax | △ | ○ | △ | △ | |

| Operability | Drag/Flick | △ | ○ | ○ | △ |

| Multi-touch | X | ○ | ○ | ○ | |

| Glove-touch | ○ | △ | ○ | ○ | |

| Durability | Keystroke/Sliding | △ | ○ | ○ | ○ |

| Water resistance | △ | ○ | △ | X | |

| Light resistance | ○ | ○ | △ | ○ | |

| Usage | Automotive Printer FA |

Smart-phone Tablet Automotive |

Signage Ticket-vending machine ATM |

Ticket-vending machine Public terminal ATM |

|

Features of our resistive touch panel

Panasonic’s resistive touch panel has the following features.

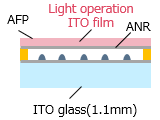

- Light operation

- High reliability to pass automotive standards

- Correspondence size ~15 inchs

Panasonic’s resistive touch panel, which has its own assembly technology, has realized a light touch by controlling the shape.

In particular, it has been widely adopted by customers in the industrial and automotive industries.

The contact position on the X-side is detected by the back side electrode using the voltage gradient on the front side.

Coordinate detection by detecting the contact position on the Y-side with the front side electrode by the back side voltage gradient.

* In principle, multi-touch cannot be detected unless a special driver is used.

Light operation

・Dot spacer

・Optimal design for gaps, etc.

2-point touch gesture

Light operation touch sensor

+ multi-touch controller

High reliability

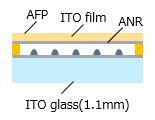

・Filler-less ITO film

・High durability dot spacer

・High reliability of constituent materials

Flat design

Decorative film lamination process

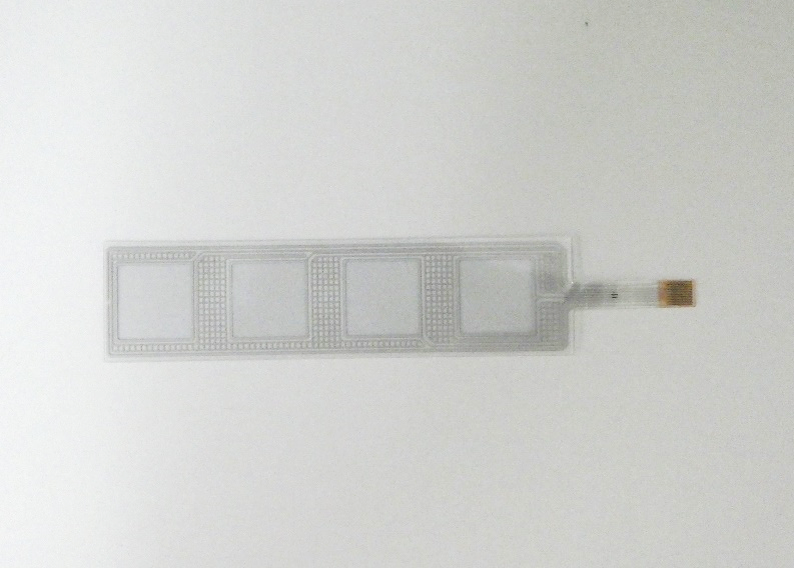

| Type | Standard type (High reliability for automotive) |

Light operation type | Flat type (with Decorative film) |

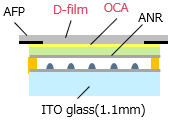

| Composition |  |

|

|

| High reliability | ○ | ○ | ○ |

| Light operation | - | ○ | ○ |

| Flat design | - | - | ○ |

| Thickness | 1.4 mm | 1.4 mm | 1.6 mm |

| Transmittance | 83% | ~86% Typ. | ~86% Typ. |

| Reflectance | 8% | 7%~ Typ. | 7%~ Typ. |

| Operating force | 0.2 N | 0.1 N | 0.1 N |

| AFP (Anti-Finger Print) |

○ | ○ | ○ |

| ANR (Anti-Newton Ring) |

○ | ○ | ○ |

Features of our capacitive touch panel

Panasonic’s capacitive touch panel has the following features.

- Being a film-type sensor, it is light, hard to break, and flexible

- High reliability to pass automotive standards

- High sensitivity with original sensor pattern

- Glove

- Hover

- Proximity sensor

- Size ~30 inches

Panasonic’s resistive touch panel, which has its own assembly technology, has realized a light touch by controlling the shape.

In particular, it has been widely adopted by customers in the industrial and automotive industries.

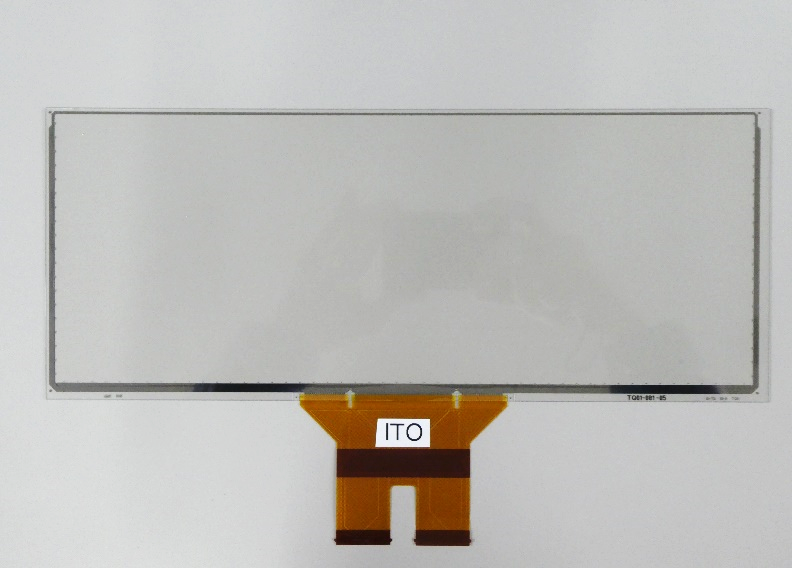

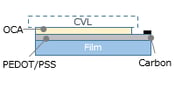

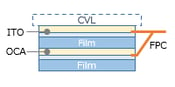

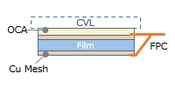

| Wiring materials | PEDOT/PSS | ITO | Metal-mesh |

| Exterior |  |

|

|

| Composition |  |

|

|

| Transmittance | △ | ○ | ○ |

| Wiring resistance | △ | ○ | ◎ |

| Curved surface (2.5D) |

≧R2 | ≧R500 | ≧R2 |

| Flame (L/S) | 250/250 um | 50/50 um | 8/8 um |

| Size | - | ~ 12 inch | ~ 30 inch |

| Usage | Capacitive switch | Capacitive touch panel | Capacitive touch panel |

Self-capacitance touch panel

From the touch controller.

Appears to have formed a capacitor (increased capacitance)

Capacitor

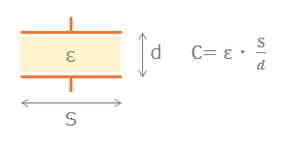

Passive elements that store and release electricity

| Materials | Dielectric constant |

| Diamond | 16.5 |

| Soda lime glass | 6.0~8.0 |

| Acrylic resin | 2.7~4.5 |

| Polycarbonate | 2.9~3.0 |

| Air | 1.00059 |

ε = ε0 (Dielectric constant of vacuum) x ε𝑠(Dielectric constant of insulator)

S: Conductor dimension

d: Conductor distance

Replace it with a touch panel…

d: Narrow distance between conductors ⇒ Thin cover panel

S: Large conductor dimension ⇒ Large finger contact dimension

ε: High dielectric constant ⇒ High dielectric constant of the cover panel

Larger capacitance ⇒ High sensitivity

Touch detection flow

The touch controller converts the capacitance into a digital value, and if the value exceeds

Self-capacitance slider

By “determining the center of gravity” from the capacitance value of each electrode, even with a small number of electrodes High-resolution coordinate output is possible.

It can be realized by arranging two independent sliders orthogonally.

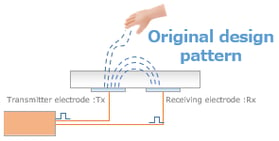

Mutual capacitance touch switch

In the mutual capacitance method, two electrodes of “transmitting” and “receiving” consist one sensor.

The voltage pulse transmitted from Tx makes an electric field (lines of electric force) and propagates to Rx.

Part of the electric lines of force flow through the finger to GND (capacitance between Tx and Rx decreases), lowering the reception level of Rx.

Based on the Rx reception level, the switch ON/OFF is detected in the same way as the self-capacitance method.

Flexible

Being a film type, it is light, hard to break, and flexible

High sensitivity

Original pattern allows plastic cover panel to be compatible with glove

High reliability

High reliability of constituent materials

Various sensor specifications

Proposal of sensor according to request

Please feel free to contact us, if you have any questions.