This article explains the selection of a suction nozzle used during connector mounting.

The mounting of small components like Panasonic’s connectors proceeds according to a process flow starting with the suction of each fed component with the mounter's nozzle followed by their transfer to their respective target positions on the printed-circuit board. When selecting such a nozzle, various considerations are necessary according to the shape of the component to be mounted.

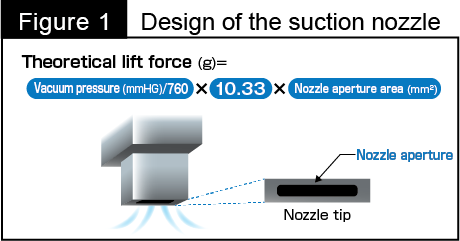

First of all, reliable suction torce must be ensured from the outset to prevent components from dropping while they are being transferred. As a guideline, it is recommended to select a suction nozzle with absorption power that can achieve a theoretical lift force more than 10 times the weight of the connector to be mounted.

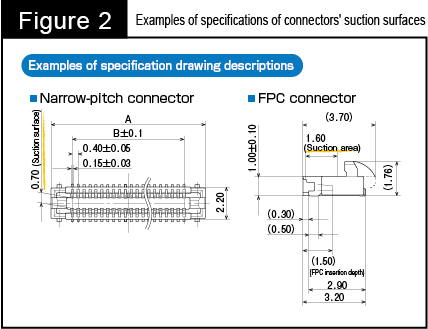

Next, it is necessary to confirm the shape and dimensions of the suction area of the actual connector to be sucked using the nozzle. Please confirm the latest specification document or user manual which corresponds to the specifications of the connectors' suction surface.

For the details of suction nozzles, please consult with the manufacturer of the mounting equipment used.

How were the above explanations? This article explained the points to confirm before selecting a suction nozzle.