In this series of lectures, we have been explaining mechanical relay specifications by answering questions from customers. The theme for today's lecture is the difference between "electrical service life and mechanical service life," which are two different kinds of service lives every mechanical relay has. This article will help eliminate your concerns and find answers to your questions when you check the specifications of your mechanical relays in catalogs.

Question:

A mechanical relay has an electrical service life and a mechanical service life. What is the difference between the electrical service life and the mechanical service life?

Answer:

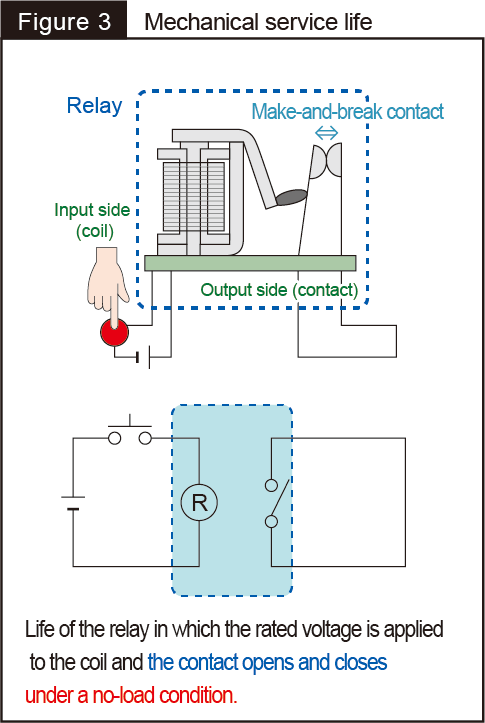

Whether or not a load connects to the contact creates this difference. The electrical service life of a mechanical relay, in general, refers to the switching life of the relay in which a rated load is connected to the contact. The mechanical service life, on the other hand, refers to the life of the relay as an operating mechanism in which no load is connected to the contact (no-load condition).

These two kinds of service lives (electrical service life and mechanical service life) are defined as follows.

1.Electrical service life

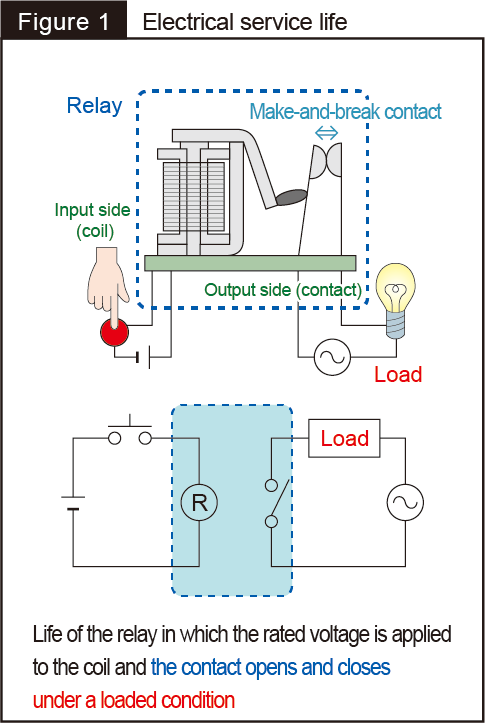

The electrical service life of the relay is determined generally by a resistance load test (see Fig. 1).

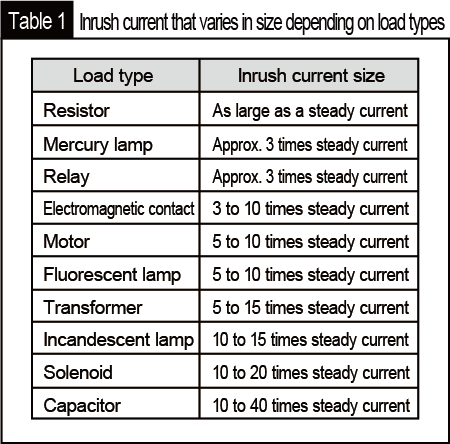

In this test, the electrical service life varies depending on the capacity and the type of load (which includes contact voltage, contact current), the frequency of opening/closing of the contact, ambient temperature, etc. Various types of loads are listed in Table 1 for your reference.

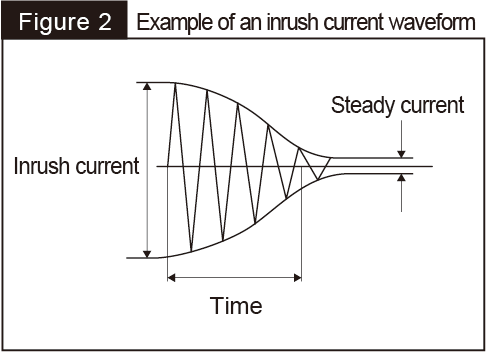

Opening or closing the contact creates an inrush current, which varies in size depending on the load type, ranging from several times to several tens of times steady current. This inrush current greatly affects the life of the relay, so you need to examine the inrush current that develops in the relay circuit carrying an actual load (see Fig. 2).

2. Mechanical service life

The mechanical service life of the relay, as mentioned above, refers to the life of the relay determined by a no-load test.

Since a relay is a component comprising of a mechanism, the relay wears out and fatigues every time it opens and closes. Its life may deteriorate quickly when it is used in an unfavorable service environment in which ambient temperature is improper or a voltage higher than the rated voltage is applied to the coil. You need to be careful about conditions under which the relay is used (see Fig. 3).

We have discussed in this article the difference between the electrical service life and the mechanical service life. We hope the article will help you in performing your circuit design work.

Keywords

- Contact:

A contact refers to the point of contact in an electric circuit where separated parts come in contact with each other to create a current-carrying path. - Coil:

A wire is wound into a coil, which causes electromagnetic induction when supplied with current. The mechanical relay operates utilizing this characteristic of the coil. - Service life:

The service life of the relay is defined as the total number of times the relay opens and closes without any problem. - Load:

A load in a relay circuit is an element to be controlled on the output side (contact side) of the circuit. - Coil rated voltage:

This is a recommended reference voltage that is applied to the coil to operate the relay normally. - Rated voltage:

This is a specific voltage that is applied to the contact. - Contact current:

Contact current refers to a current flowing through the contact.