Agile Adaptability

to Applications

Specialized for applications

Simple installation without a need for a host controller program

Specialized for applications

Application

specialized type

Servo driver

Sensor direct feedback (Displacement control)

Sensor direct feedback (Pressure control) Under Development

High-precision gantry control Under Development

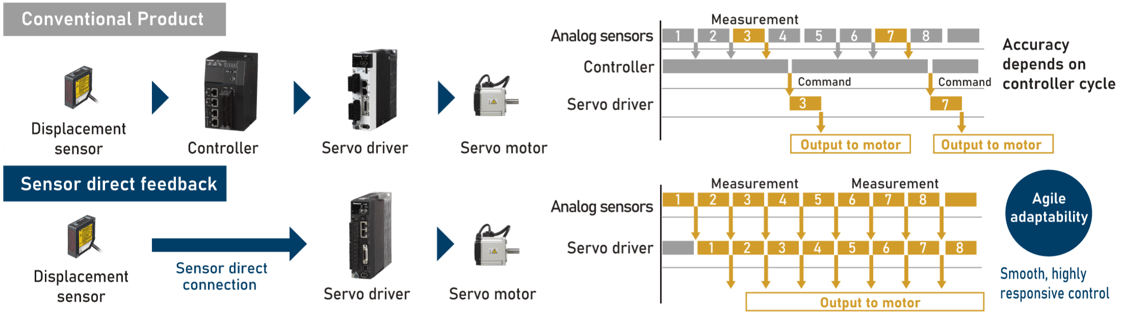

High responsiveness and smooth

control not dependent on a controller

Sensor direct feedback

Analog data from sensors, etc., is directly input to the servo driver, allowing high-speed response control simply by setting up the servo driver. This makes it possible to eliminate complex host controller programs required in the past.

Sensor Direct

feedback

Accurate position correction

according to workpiece variation

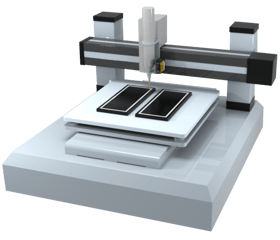

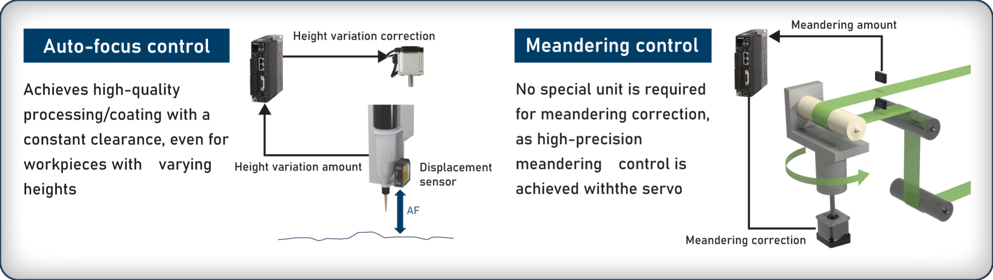

Displacement control(Auto-focus control, meandering control)

Full-closed control that is completed within the driver through direct input of the displacement sensor to the servo driver. The high-speed feedback control is not dependent on a host controller, providing a high-speed response to workpiece variations.

Applicataions

- Dispensers

- Display bonding equipment

- Scribing devices

- Laser processing machines

- Lithium-ion battery winding machines

- Packing machines

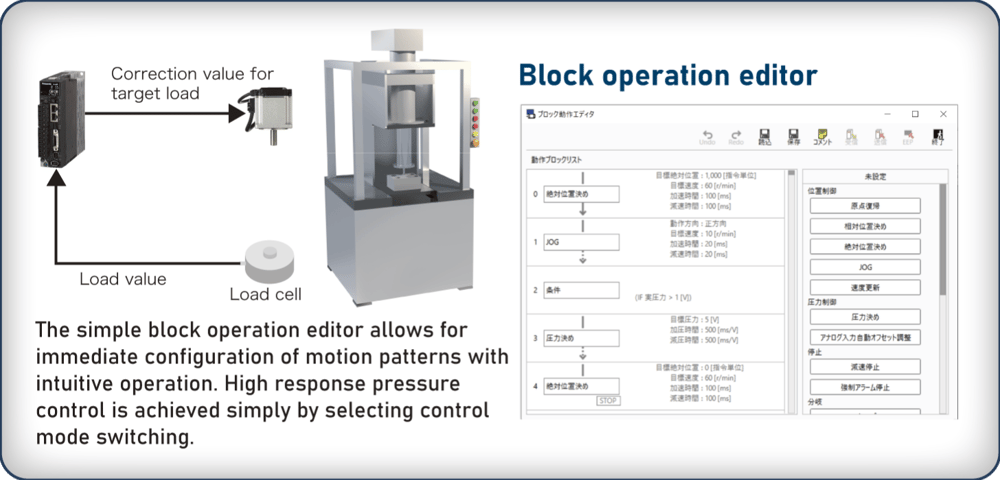

Sensor direct feedback

Simplifies complex control programs for stable,

highly precise pressure control

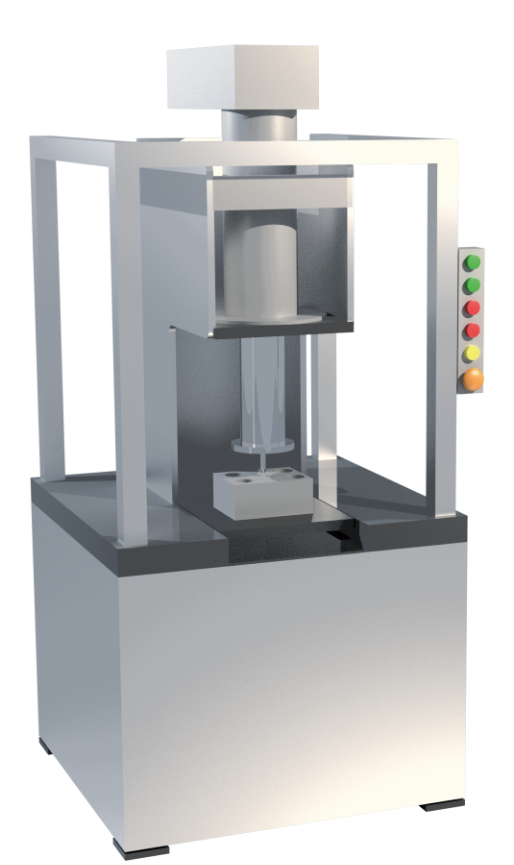

High-precision gantry control Under Development

Advanced coordination control, ease of use and safety functions ideal for gantry mechanisms

Applications

- Press machines

- Bonding equipment

- Assembly equipment

- Press fitting equipment

- Capping devices

- Screw tightening equipment

Gantry control model

Advanced coordination control, ease of use andsafety functions ideal for gantry mechanisms

High-precision gantry control Under Development

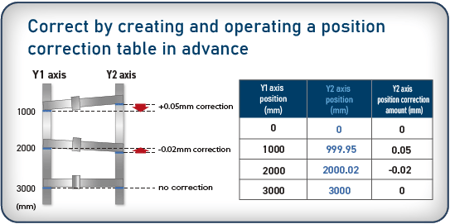

Precise

Torsion correction (Table )

Measure positional deviation between two axes beforehand

and save as a table to correct torsion and improve positioning

accuracy.

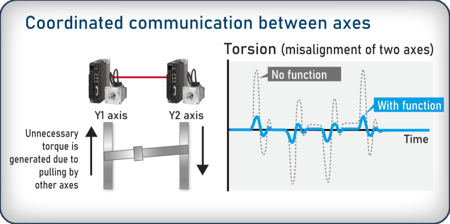

Faster

Torsion correction (Real-time )

Torque interference is reduced by detecting and correcting

torsion between axes in real time, enabling high speed

operation.

Simpler

Gain adjustment optimization

Gantry mechanism adjustment, which used to require complex

adjustments, is now quicker and easier.

Safer

Coordinated stoppage during an alarm

When an alarm occurs on one axis, the two axes are stopped in a

coordinated manner to prevent mechanical damage.

Applications

- Bonding equipment

- Substrate inspection equipment

- Scribing devices

- Grinding equipment

- Mounters

- Laser processing machines