Use-case

Meeting the need for further miniaturization and increased processing accuracy

Contributing to improved equipment performance

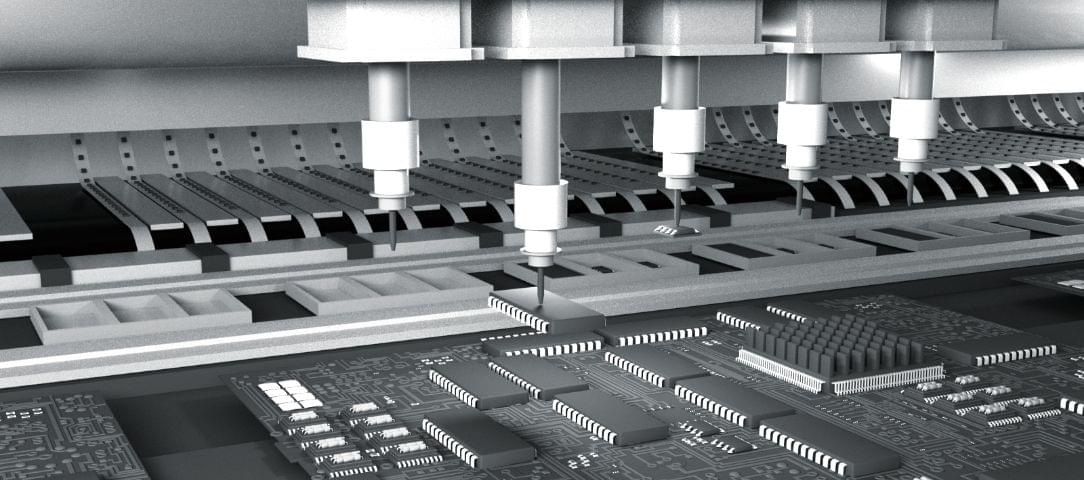

Semiconductor manufacturing process

In response to the demand for miniaturization and multi-layering of semiconductor chips, higher speed and higher

precision control is required in each manufacturing process.

Spin coaters

Chemical solutions are evenly spread by rotating the wafer.

The high-speed rotation contributes to increased thinness.

Max. motor rotational speed 7150 r/min

Dicing saws

By improving positioning accuracy, micro IC chips can be

formed from wafers.

Improved positioning accuracy

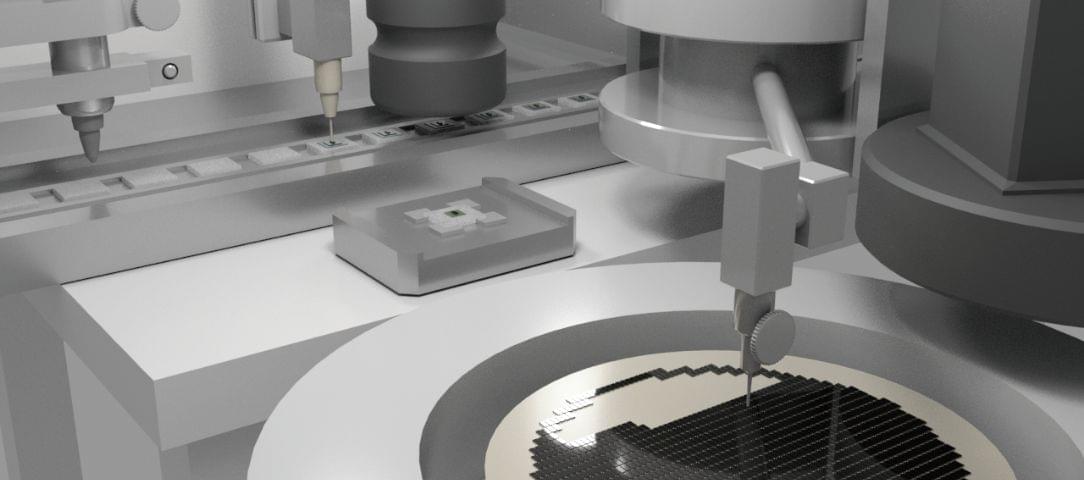

Chip transfer machines

Suppresses minute tip vibrations and realizes high-speed

pick & place of microscopic IC chips.

precAIse TUNING

Bonding equipment

High-response load control prevents mounting failures and

damage to microchips during substrate mounting.

Sensor direct feedback (Pressure control)

IC handlers

Abnormal stops due to overloading are reduced, even when quick acceleration/deceleration is repeated under high load conditions.

Extending overload operation time

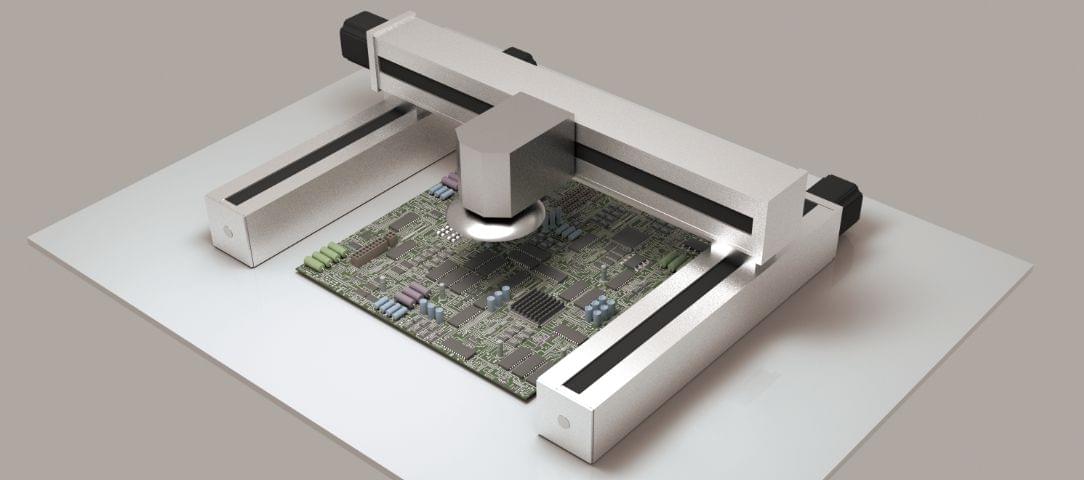

Substrate inspection equipment

The dual axes of the gantry mechanism allow for smooth, high-speed operation, enabling high-speed inspection

High-precision gantry control

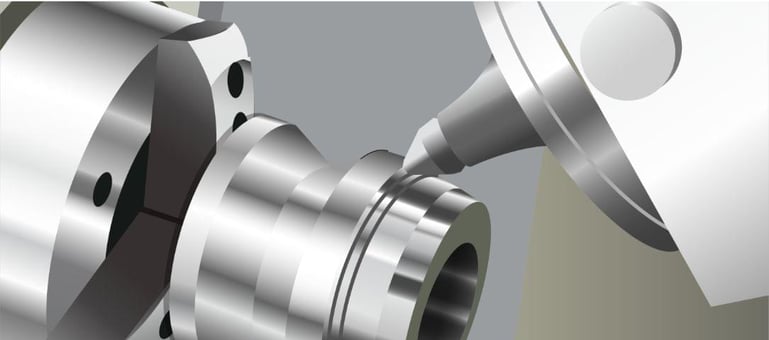

Processing machinery

As products become denser and more sophisticated, higher precision control is required for all machines, even

those that process the individual parts making up the product.

Metal processing machines

The high-response servo can increase the gain, enabling ultra-precise, nanometer-order machining.

Encoder resolution 27 bit

Velocity response frequency 4.0 kHz or more

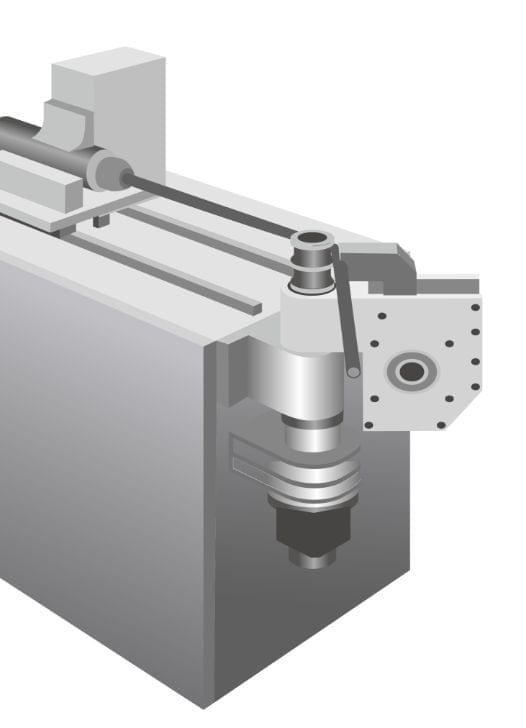

Laser processing machines

High-quality machining is achieved by correcting unevenness

with regard to height with a high level of responsiveness.

Sensor direct connection auto-focus control

Press machines

Operation patterns for

high-response pressure control

can easily be constructed

without a host program.

Block operation function

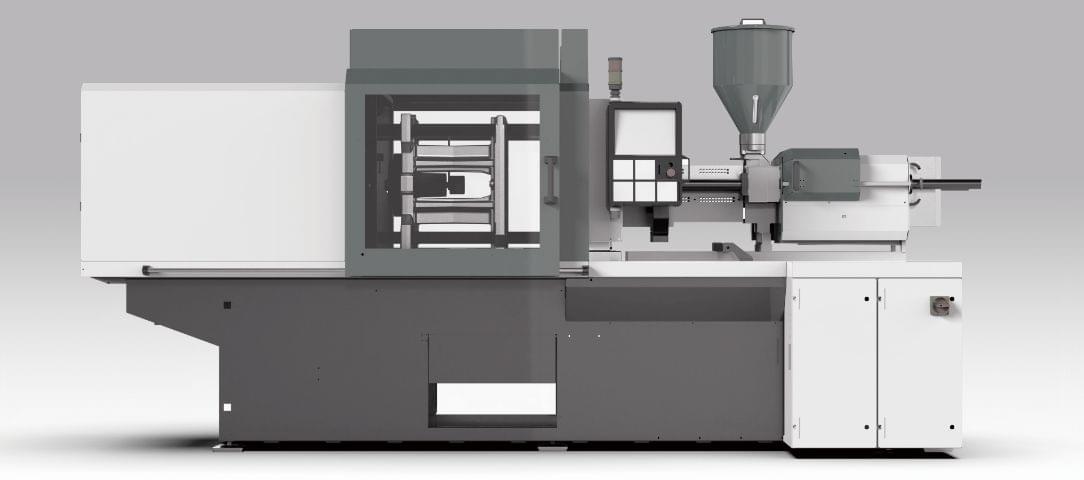

Injection molding machines

High-response pressure control stabilizes filling pressure

and suppresses filling defects and burrs.

Sensor direct feedback (Pressure control)

Pipe bending machines

Both position control and

pressure control are fully

closed within the servo,

achieving high speed and

accurate bending.

Sensor direct feedback

(Pressure control)