Agile Adaptability

to Machines

Improving basic performance allows for

immediate response to commands and disturbances

Improved basic performance directly linked to equipment performance

Servos boasting industry-leading motion performance

*As of September 2023, according to in-house research

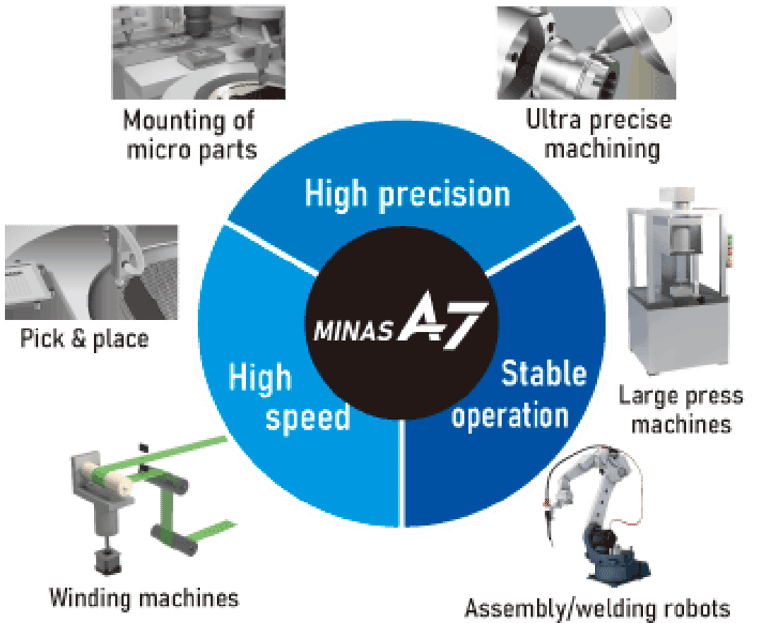

High precision

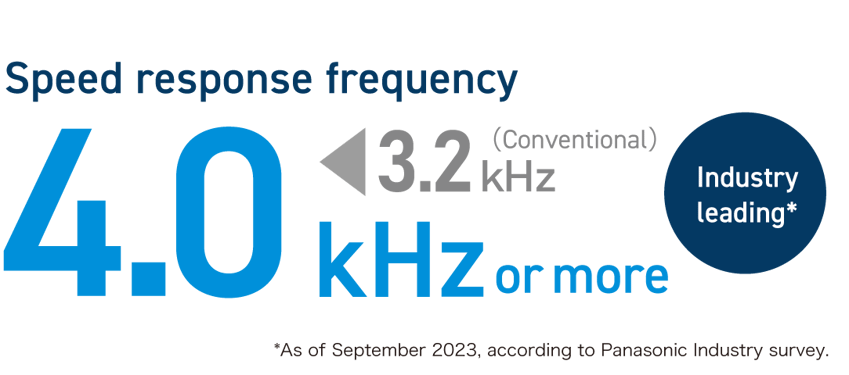

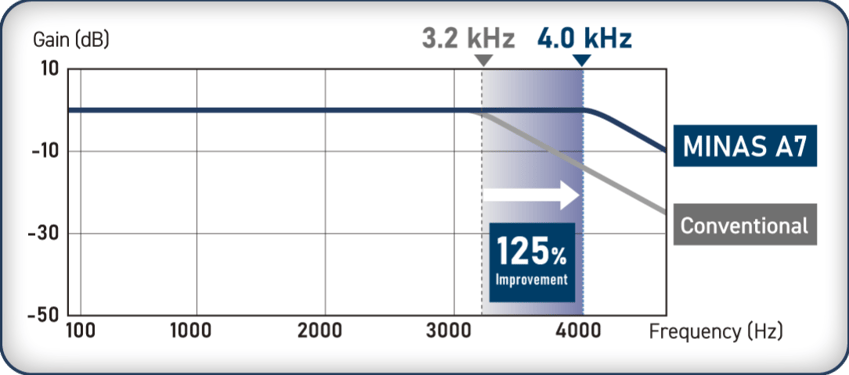

Control performance that achieves smoother and more accurate operation

Improved machining quality through high response control

Speed response frequency has been increased to 125% compared to conventional models. As gain can be increased, an immediate response to both commands and disturbances is possible, improving machining quality.

Improved positioning performance

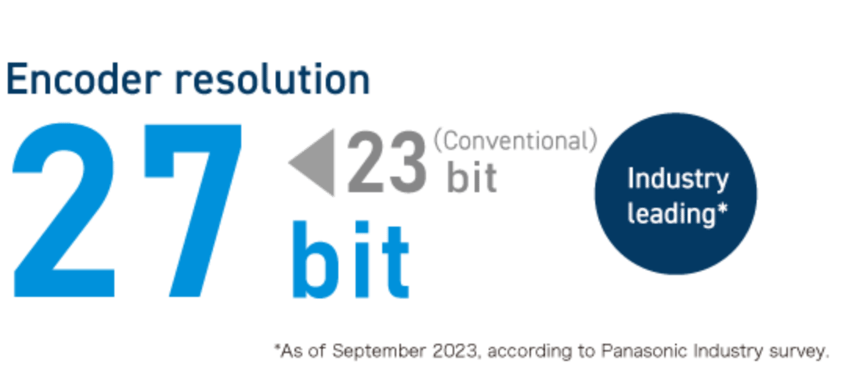

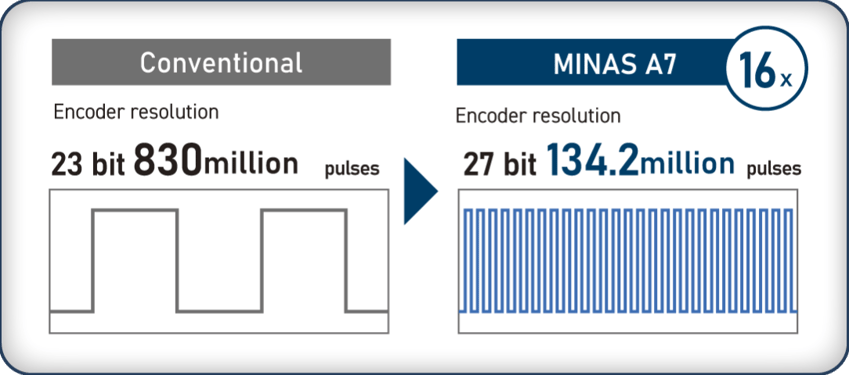

Thanks to the industry’s highest* resolution, positioning performance is greatly improved with smooth movement to the target position and accurate stopping.

High speed

Increased speed for a shorter takt time

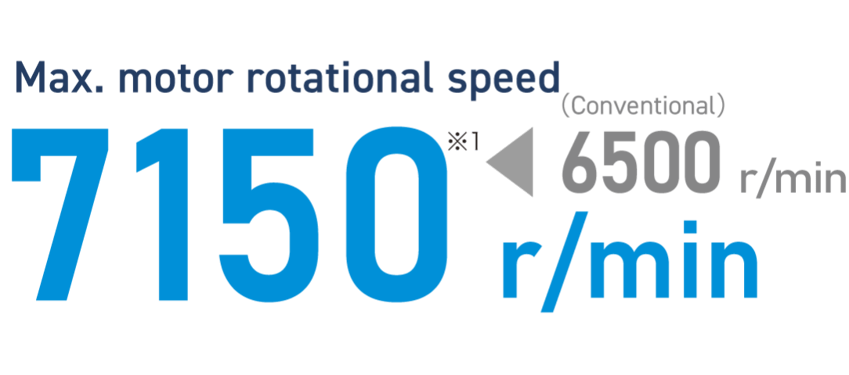

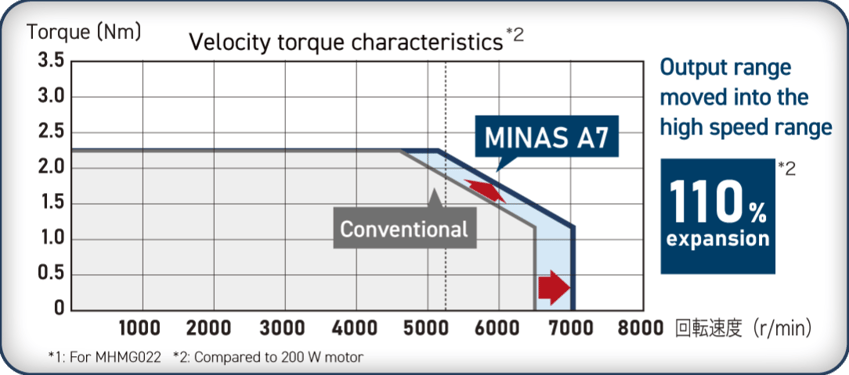

Increased output without changing the size of the motor

The MINAS A7 is smaller than conventional models, and the operation range has been expanded to 110%*2. By expanding output to the high speed range, equipment velocity has been improved without changing to a larger motor.

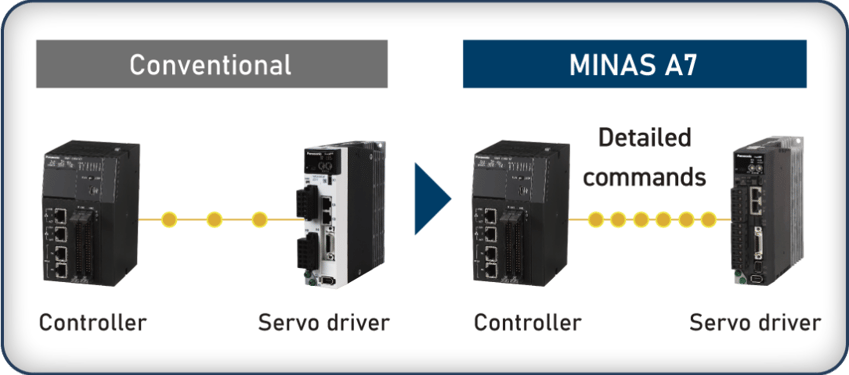

High precision with detailed command output

Minimum communication cycle is 1/2 that of conventional models. It can respond to the control cycle of controllers that are becoming ever faster, allowing for more detailed control.

Stable operation

Continuing “tougher” operation

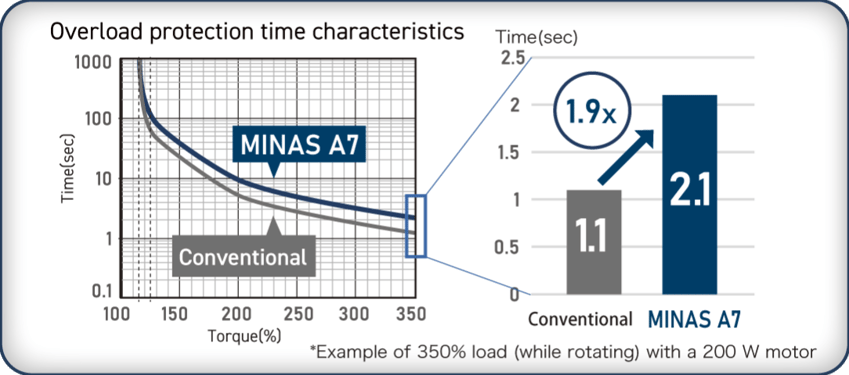

Extending overload operation time

Reducing the heat generation of the motor extends operating time during overload by 1.9 times compared to conventional models. This contributes to the stable operation of equipment that operates for long periods of time in high-load areas, such as press machines and robots.

Space saving

“More flexible” installation

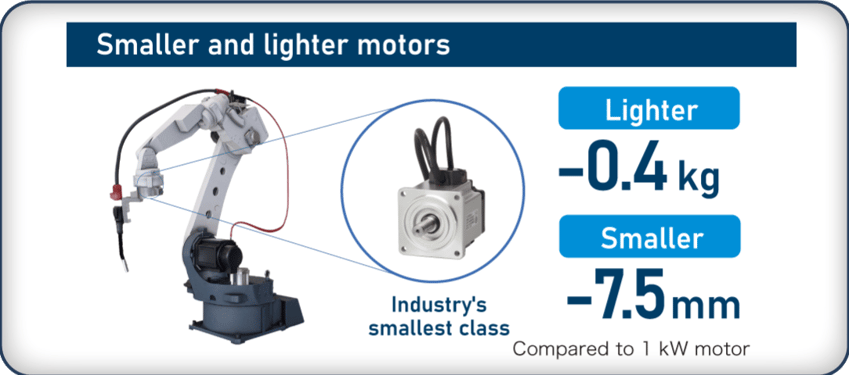

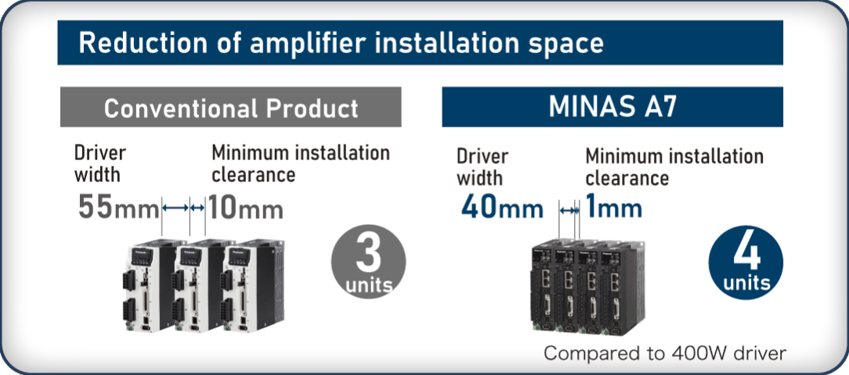

Further miniaturization and space saving

Both servo motors and amplifiers have been further miniaturized. The motors contribute to improved control performance by reducing the size, weight, and inertia of robots and equipment in which the motors are used.

Stop precisely at the target position

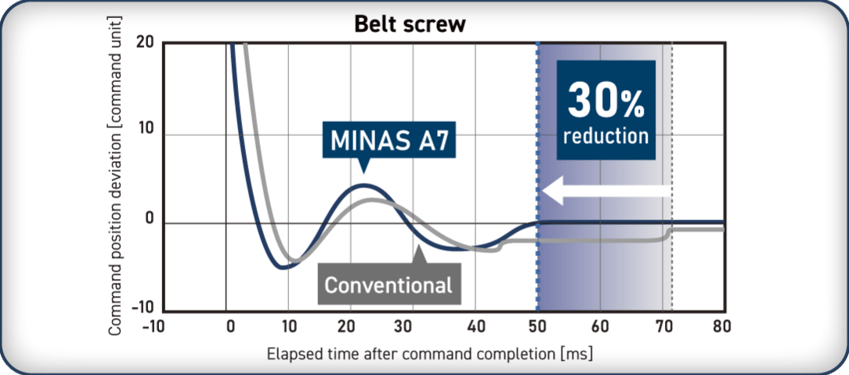

Improved positioning setting time

In addition to improved motor and encoder performance and an evolution of our proprietary positioning algorithm, resonance and mechanical vibration are automatically removed for highly accurate positioning.

Contributing to improved equipment performance