Agile Adaptability

to people

Optimal man-machine coordination

during tuning is achieved through servo intelligence

Immediate response even at start-up

From simple adjustments to ultra-high precision tuning that require expert skill

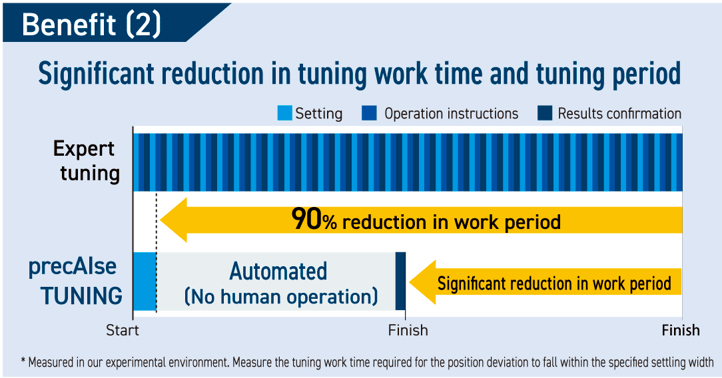

Automatic tuning reduces startup engineering man-hours

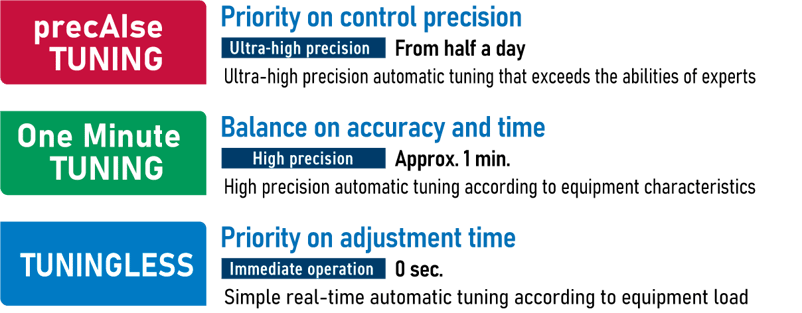

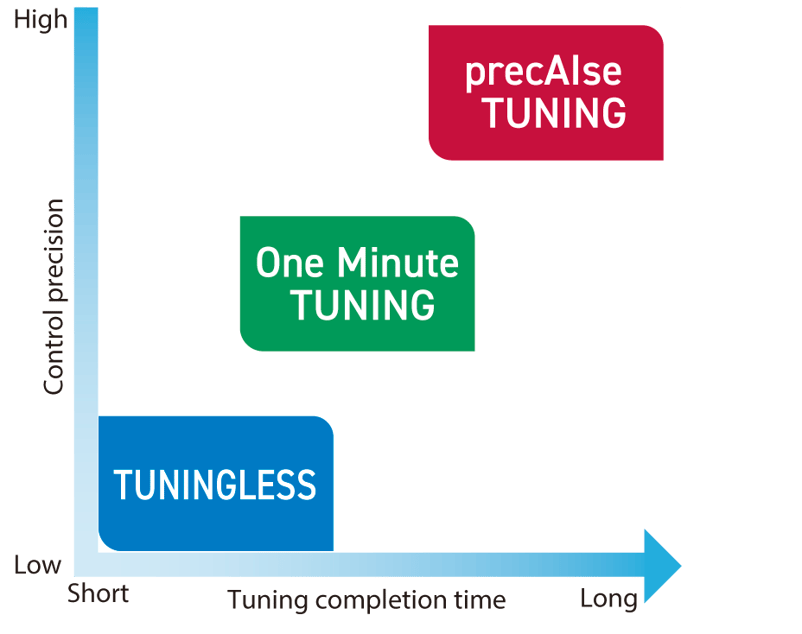

Three tuning settings can be selected according to whether you wish to prioritize tuning time or control precision

It is possible to select the optimal tuning method to match customer requests, from situations that require tuning difficult for even expert engineers to those that require immediate operation.

* TUNE COMPASS is a trademark of Panasonic Holdings Corporation.

Immediate operation

Automatic adjustment according to the equipment load during operation, toeffortlessly achieve stable operation.

Every time the equipment is moved, the servo driver automatically carries out simple real-time tuning according to the equipment load.

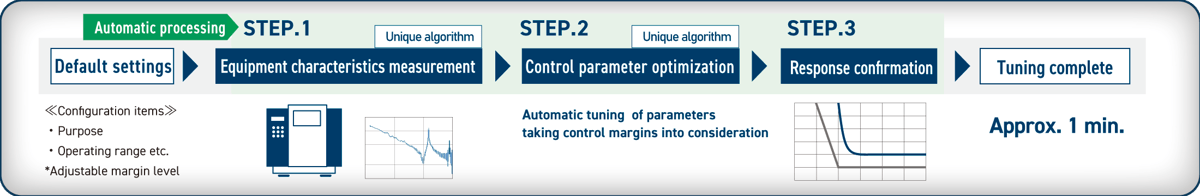

High precision

The driver understands equipment characteristics and implements tuning while taking control margins into consideration.

With only a simple initial setup, the three-step tuning process, including measurement of equipment characteristics, is performed automatically and optimized in a short time.

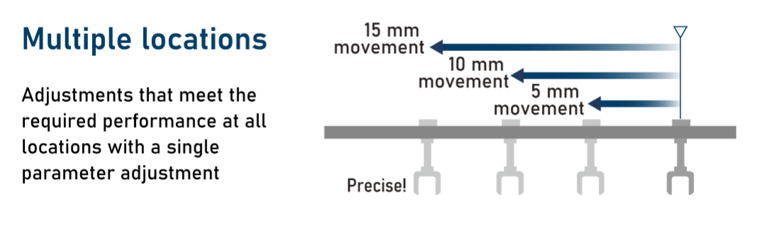

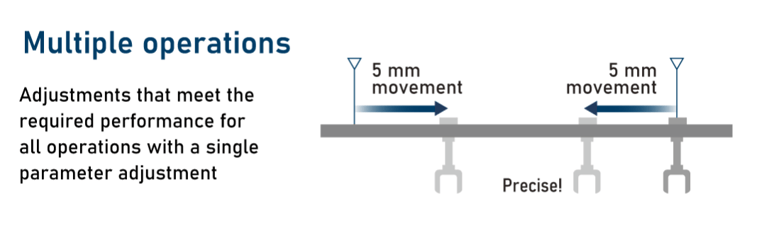

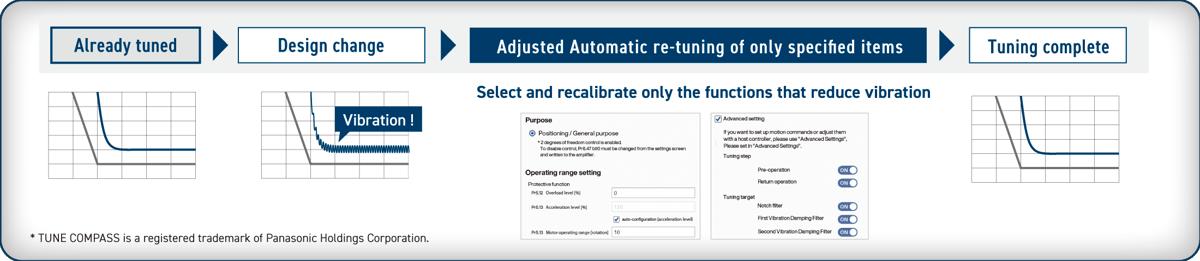

Automatic re-tuning of specific items with pinpoint accuracy in response to material and location changes

Ultra-high precision

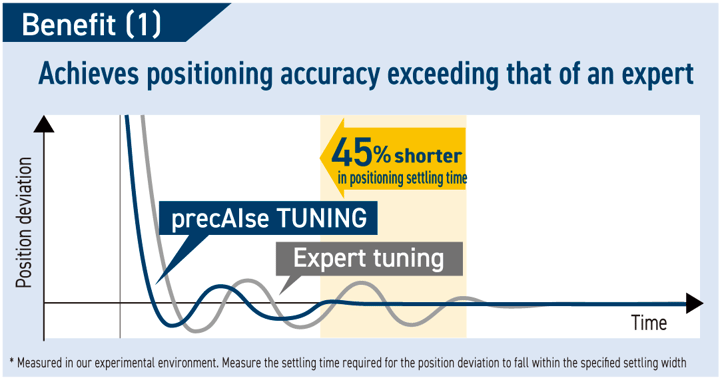

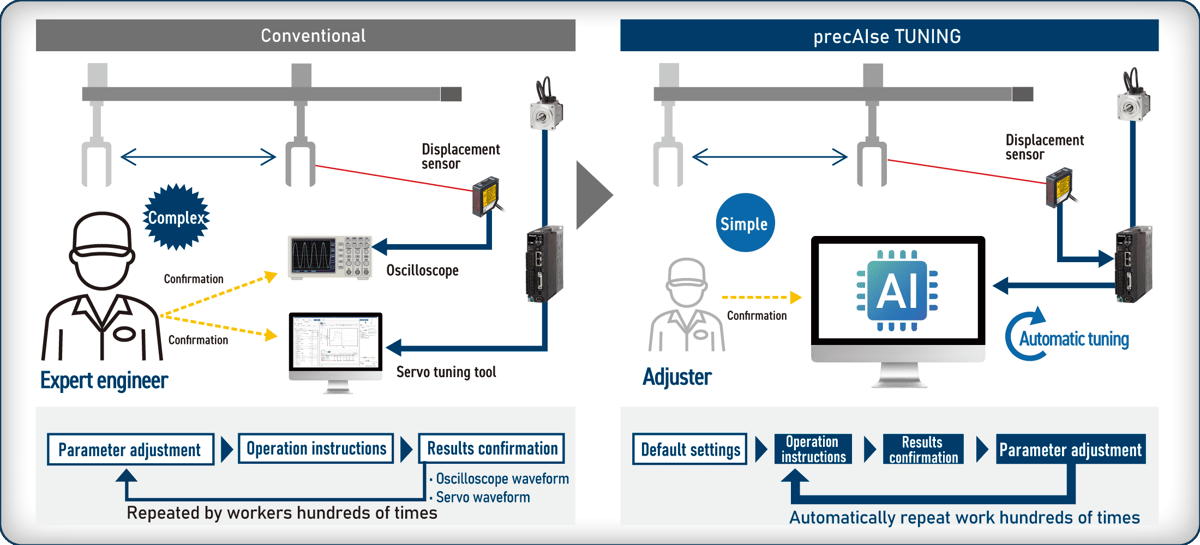

The AI uses expert judgment to easily achieve ultra-high precision tuning

Complex tuning that take several days even for expert engineers are automatically optimized by AI just by setting the conditions, making μm level ultra-high precision tuning easily achievable.

[Applicable equipment]]

Equipment such as mounters, coating equipment and processing machines

which require ultra-precise positioning accuracy

Ultra-high precision tuning automatically performed by AI that exceeds the abilities of experts

High level of automatic tuning satisfies performance requirements for all locations and operations